AI in Manufacturing: Revolution & Case Studies

AI is revolutionizing production in today’s industrial landscape by facilitating informed decision-making and increasing productivity. The integration of AI technology in manufacturing revolutionizes the sector, with the global AI market projected to reach GBP 12.6 billion by 2027, per Markets and Markets.

AI in manufacturing improves output, accuracy, and productivity while supporting supply chain management, demand forecasting, quality control, and operational simplification. The integration of cutting-edge technology offers a strategic opportunity for expansion and competitiveness in manufacturing, thanks to the benefits of artificial intelligence. This blog post explores diverse use cases illustrating how AI is reshaping manufacturing processes, demonstrating its practical utility and transformative potential for businesses in this sector.

Understanding AI in Manufacturing

Manufacturing is changing dramatically because to artificial intelligence, which can uncover inefficiencies in production and automate procedures. Its ability to process enormous amounts of data—whether from machinery or human inputs—has transformed operations and produced consistently high-quality results that adhered to rules and regulations in the sector. Additionally, AI has facilitated advancements in production design, a critical element in driving innovation within the manufacturing landscape.

According to a study conducted by PwC, Reinforcement Learning, a subset of AI, exhibits the potential to revolutionize electronic device production within smart manufacturing. This technology dynamically adjusts machine parameters, optimizing production processes. By maximizing production through constant learning and adaptation, reducing errors, and optimizing resource consumption, the system keeps a competitive edge and boosts profitability.

Overall, AI transforms production by fostering innovation, reducing costs, and enhancing operational efficiency. Let’s explore key manufacturing AI applications for insight.

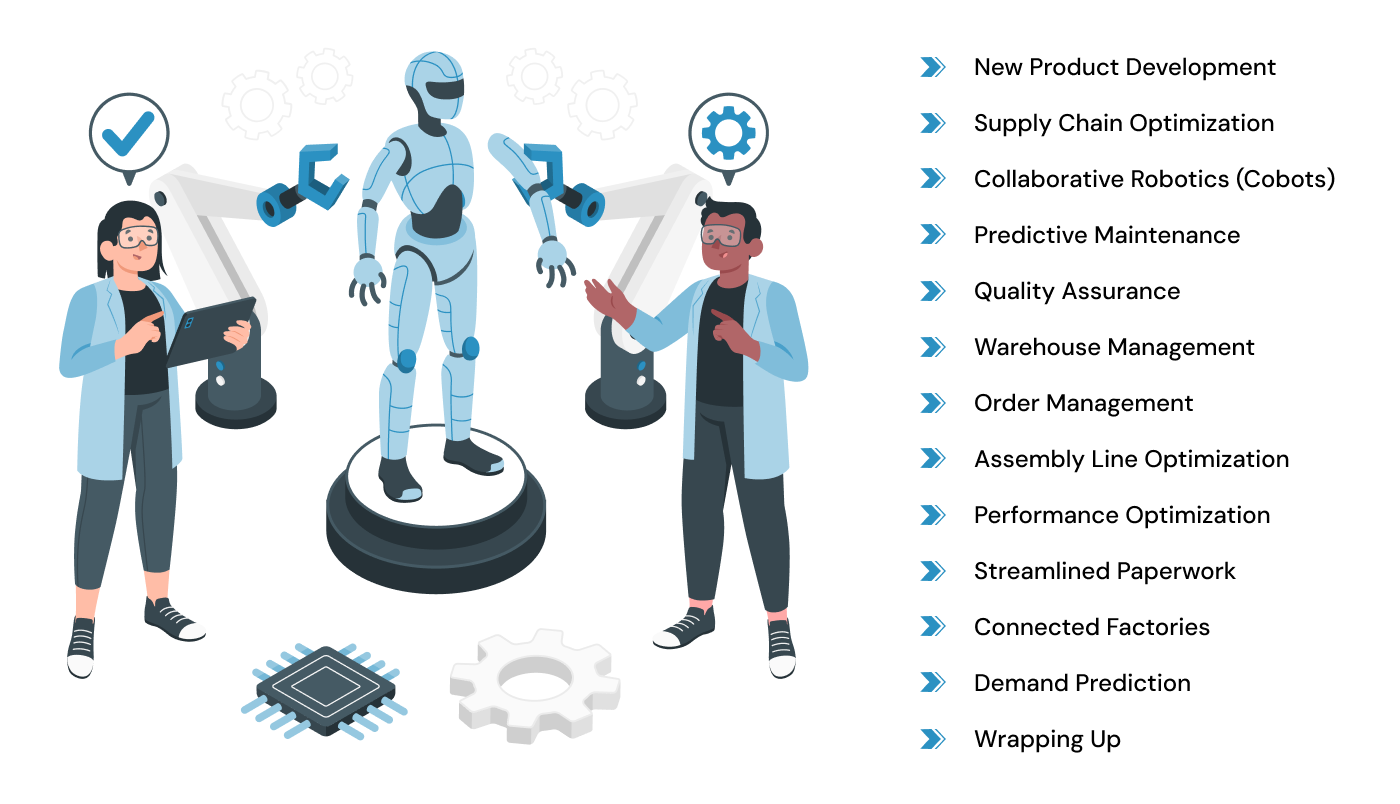

AI in Manufacturing: Innovative and Real-World Examples

AI transforms manufacturing with unprecedented breakthroughs and efficiencies, revolutionizing the industry. Below are twelve notable instances where AI is reshaping manufacturing, supported by tangible examples.

New Product Development:

With the introduction of AI, the field of new product creation in manufacturing has experienced a dramatic change. AI integration in manufacturing has revolutionized the way businesses launch new items on the market by bringing creative solutions and efficient procedures.

AI’s capacity to swiftly and efficiently analyze vast data sets is a pivotal advantage in manufacturing’s new product development. Employing machine learning algorithms enables manufacturers to make data-informed decisions on product design, extracting insights from competitor analyses, market trends, and consumer preferences.

For instance, semiconductor companies leverage machine learning to predict component failures, anticipate issues in new designs, and optimize layouts to enhance yield in IC design.

Generative design software exemplifies AI’s impact on new product development, utilizing generative AI to expedite design iteration processes and facilitate optimized product designs. This application of AI accelerates new product creation by exploring design alternatives rapidly based on specific business objectives.

The semiconductor industry further illustrates AI’s influence on manufacturing and production. GPU manufacturers like NVIDIA employ AI to analyze large datasets on component architectures, foresee potential issues with chip designs, and optimize semiconductor layouts. AI analytics cut costs, boost yields, and accelerate product launch, showcasing its role in fostering innovation and data-driven decisions.

Supply Chain Optimization

Artificial intelligence (AI) disrupts supply chain management by improving accuracy, efficiency, and cost-effectiveness. Artificial Intelligence (AI) technology is revolutionizing supply chain activities by enhancing industrial processes. Predictive analytics enables precise demand forecasts, effective inventory control, and simplified logistics.

Algorithms that use machine learning examine past data, identify trends, and precisely predict changes in demand. A manufacturer of auto parts utilizes ML to predict demand, maximizing inventories and reducing expenses.

Leading multinational retailer Walmart heavily uses artificial intelligence (AI) in supply chain management to increase efficiency and customer satisfaction. The massive retail chain uses machine learning algorithms to estimate consumer demand, examine historical sales information, and efficiently manage inventory levels. Walmart mitigates excess inventory expenses, avoids stockouts, and assures product availability via AI-driven demand forecasting. Additionally, Walmart enhances logistical operations through the use of AI-powered routing algorithms, enabling faster and more economical delivery. Walmart is a shining example of how cutting-edge technology improves decision-making and overall resilience in the retail industry. Walmart uses artificial intelligence (AI) to manage its supply chain. This illustrates how supply chain responsiveness and efficiency may be increased in the fiercely competitive retail industry through the use of cutting-edge technologies.

Collaborative Robotics (Cobots)

AI-driven production requires collaborative robots, or cobots for short, because they boost output by assisting human operators. Among other things, they assist with packing and selection at fulfillment facilities. These cobots use AI algorithms to detect things and navigate complex locations while working side by side with human workers.

For example, Amazon utilizes cobots empowered by machine learning to expedite order fulfillment, optimize logistics, and refine operational processes. These AI-infused robots exhibit precision and adaptability in executing complex tasks. They handle intricate assembly processes and quality control inspections while seamlessly cooperating with human counterparts. This cooperative strategy guarantees optimal equipment performance, lowers maintenance costs, and minimizes downtime. Because they boost efficiency by assisting human operators, collaborative robots, or cobots for short, are crucial to AI-driven manufacturing. They assist with packing and selection among other tasks when working in fulfillment facilities.

Predictive Maintenance

Predictive maintenance has the potential to revolutionize the industrial sector thanks to artificial intelligence. AI helps companies anticipate and proactively monitor equipment failures, which minimizes downtime and improves maintenance schedules. It uses advanced machine learning and predictive analytics techniques to achieve this.

Predictive maintenance revolves around the concept of the “digital twin,” a virtual asset that replicates a physical asset’s activity and records data in real time. Production-level artificial intelligence (AI) may combine sensor data with the digital twin to identify trends, identify anomalies, and predict potential errors. The use of AI-powered predictive maintenance at the Ford factory is a prime example of its application in the manufacturing sector. Ford creates distinct digital twins for each vehicle model, covering various production areas from concept to operation. These digital twins help to improve overall production line performance, pinpoint energy losses, and optimize manufacturing processes.

AI’s predictive maintenance, with digital twins and advanced analytics, revolutionizes manufacturing, enhancing efficiency and cost-effectiveness.

Quality Assurance

Higher levels of precision and consistency are being ushered in by the integration of AI in manufacturing, which is transforming quality control methods. Manufacturers use AI technology to examine photos or videos of items and components using computer vision algorithms. These algorithms perform better than humans in detecting flaws, irregularities, and departures from quality norms with unmatched accuracy.

Foxconn, a well-known electronics manufacturer, provides a concrete illustration of how AI is affecting manufacturing quality control. By incorporating AI and computer vision technology into its production lines, Foxconn has improved the quality control processes of its operations. Artificial intelligence (AI) systems use picture and video analysis to quickly and accurately identify defects in electronic components, guaranteeing that strict quality criteria are met. This application of AI enhances production efficiency and accuracy, empowering firms like Foxconn to deliver high-quality goods at scale within the dynamic electronics sector. Predictive quality assurance is another area where AI trends in manufacturing are present. Through the examination of both past and present sensor data, machine learning algorithms identify patterns and trends that may point to possible quality problems. By taking a proactive stance, producers can anticipate problems and take corrective action before they have an adverse effect on the quality of the finished product.

Warehouse Management

With AI-powered solutions, warehouse management in the industrial sector is being transformed by increasing accuracy, efficiency, and cost savings. By precisely predicting demand using sales data, inventory levels, and market trends, artificial intelligence (AI) improves inventory management. Warehouses can minimize carrying costs and increase product availability using this optimization. BMW uses AI-driven AGVs to improve warehouse inventory control, simplifying intralogistics for better management and visibility. By optimizing inventory and expediting order fulfillment, artificial intelligence (AI) integration in manufacturing improves warehouse operations and boosts productivity and cost-effectiveness.

Order Management

Order management is transformed by artificial intelligence, which streamlines and optimizes the entire order fulfillment process. AI uses machine learning algorithms to assess historical data, consumer preferences, and market trends in order to precisely estimate demand. This makes it possible to process orders automatically, optimize inventories, and make dynamic pricing changes. Additionally, AI enhances fraud detection, lowering the dangers associated with fraudulent orders.

Artificial intelligence (AI) solutions encourage adaptable, customer-focused order fulfillment strategies and accelerate decision-making, which increases the effectiveness of order management systems in the manufacturing industry. AI solutions provide data-driven insights and automate repetitive tasks for a variety of enterprises.

The IBM Watson Order Optimizer is a great example of how AI is being used in order management. IBM’s technology analyzes historical order data and consumer behavior using AI and machine learning algorithms to optimize order fulfillment procedures. Businesses can lower expenses, increase customer happiness, and boost overall efficiency by dynamically modifying inventory levels and suggesting effective order routing tactics.

Assembly Line Optimization

AI plays a key role in assembly line optimization, which improves industrial processes’ flexibility, efficiency, and accuracy. Machine learning algorithms also enable predictive maintenance, save downtime, and optimize workflow by evaluating historical performance indicators and real-time sensor data. By spotting defects or abnormalities, computer vision systems powered by AI guarantee the quality of the product.

Intelligent automation reduces waste and maximizes resource use by modifying production parameters in response to changes in demand. Through constant learning and adaptation, AI creates settings that are data-driven and adaptable, which increases productivity, reduces costs, and maintains strict production standards.

Volkswagen serves as a prominent example of leveraging artificial intelligence in the manufacturing industry. They optimize assembly lines by employing AI-driven solutions to enhance production effectiveness and quality. Volkswagen utilizes machine learning algorithms to analyze sensor data from the assembly line, forecasting maintenance requirements, and streamlining operations.

Performance Optimization

Manufacturing performance optimization is critical, and artificial intelligence (AI) is driving revolutionary change in this field. In order to find patterns, spot abnormalities, and create data-driven forecasts, artificial intelligence (AI) systems examine both past and current data. This allows manufacturers to enhance equipment efficacy and streamline operations while reducing downtime.

General Electric (GE) offers a practical example of AI’s impact on factory performance optimization. GE analyzes massive amounts of data from sensors and historical records by incorporating AI algorithms into its industrial processes. This allows GE to identify trends, anticipate equipment problems, and optimize operations. This proactive strategy boosts manufacturing efficiency, lowers equipment downtime, and increases overall equipment effectiveness.

Streamlined Paperwork

Robotic process automation (RPA) is a major use of AI and machine learning in industry, particularly in the automation of paperwork. Manufacturing processes typically involve a lot of paperwork, such as invoices, purchase orders, and quality control reports. These labor-intensive, error-prone manual procedures cause delays and inefficiency.

Conversational AI implementation in manufacturing automates these paperwork processes. Intelligent bots equipped with AI capabilities seamlessly extract data from documents, classify information, and input it into relevant systems.

For instance, Whirlpool leverages RPA to automate manufacturing operations, particularly on the assembly line and material handling tasks. RPA bots handle repetitive and rule-based tasks, ensuring accuracy and productivity throughout the manufacturing process. Additionally, Whirlpool employs these bots for quality control inspections, leveraging automation to enhance uniformity and accuracy in assessing finished products. By streamlining operations and automating quality assurance procedures, Whirlpool maintains high standards of product quality.

Connected Factories

Connected factories exemplify the integration of artificial intelligence into production processes, creating intelligent, networked ecosystems. AI in manufacturing evaluates real-time data from machinery, anticipates maintenance needs, and streamlines operations using IoT sensors.

This networked system enables efficient machine-to-machine communication, facilitating rapid adjustments to production schedules in response to demand changes. Predictive analytics enhance decision-making, ensuring seamless operations.

Notably, General Electric (GE) leverages AI-based connected factories through its Predix platform. Integrating artificial intelligence with the Internet of Things (IoT), GE monitors equipment health, predicts maintenance needs, and optimizes production lines. Through data analysis and machine learning, the Predix platform minimizes downtime and boosts efficiency in GE’s factories.

Demand Prediction

The utilization of artificial intelligence in manufacturing for demand prediction yields several benefits. Primarily, it enables data-driven decision-making by analyzing historical sales data, market trends, and external factors. This empowers companies to anticipate demand fluctuations and adjust production accordingly, mitigating the risk of stockouts or excess inventory.

For instance, envision a fashion products manufacturer leveraging AI to forecast demand for various clothing items. By analyzing data from diverse sources such as social media trends and weather forecasts, the AI system provides accurate predictions. This enables the retailer to optimize inventory levels and ensure the availability of popular items, enhancing operational efficiency and customer satisfaction.

Wrapping Up

Throughout the blog, the diverse applications of artificial intelligence in manufacturing underscore its pivotal role in transforming numerous facets of the industry. Ranging from supply chain management to predictive maintenance, the integration of AI into manufacturing processes has markedly enhanced efficiency, precision, and cost-effectiveness.

Happy Reading!!